Bosai Solution ID : JBP00080

Slope Stabilization Anchor Work / Water Collection Well Construction for Landslide Prevention

Dual Tube Rotary Percussion Drilling Method by the Arrow Drill (Rotary Percussion Drill)

Hazard

Solution Purpose

Solution Theme

Technology Subject

Advantages

The Arrow Drill (Rotary Percussion Drill) having rotation, feed and percussion mechanism rapidly drills a borehole to install a work object (anchor body or water drainage pipe) in the slope stabilization anchor work or the water collection well construction for landslide prevention.

The work object is installed securely through the outer rods remained in the borehole, which prevents borehole wall from collapsing.

The work object is installed securely through the outer rods remained in the borehole, which prevents borehole wall from collapsing.

Solution Illustrated

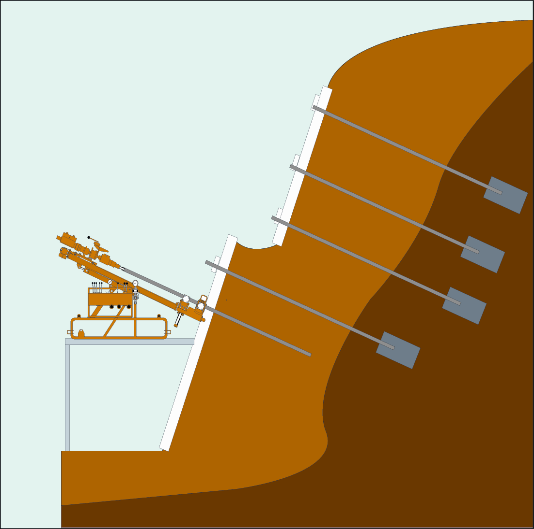

Slope Stabilization Anchor

The slope stabilization anchor is the method to counteract the landslide force using the tensile strength of the anchor body rooted in the basement.

After drilling an anchor hole with the dual tube rotary percussion drilling method, the inner rods are fully retracted and the anchor body is installed through the outer rods. Grouting is done during the outer rods retracting.

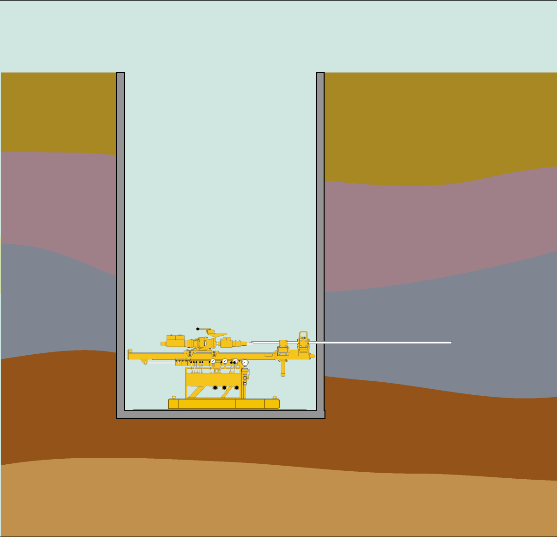

Water Collection Well

The water collection well is the method to slow down and/or prevent landslide activity by draining ground water above the slip surface.

Several dewatering holes are drilled horizontally but slightly upward direction and fan-shapely in the water collection well (the vertical shaft).

After drilling a dewatering hole with the dual tube rotary percussion drilling method, the inner rods are fully retracted and the water drainage pipes are installed through the outer rods. The outer rods are retracted remaining the water drainage pipes in a borehole.

Background

The slope disaster broken out by an earthquake and/or a concentrated heavy rain causes serious damage in various places regardless of domestic and overseas.

According to HP of the Ministry of Land, Infrastructure, Transport and Tourism, however, there are approximately 1.1 million spots in danger of landslide outbreak, in which the ratio of countermeasures taken is only 23 %, therefore it is required to take prompt countermeasures.

Originally, the single tube rotary drilling method is applied for a borehole drilling, so that the collapse of the borehole wall used to occur depending on the geological character resulting that the drilling to the predetermined depth or the installation of the work object into the drilled borehole has difficulty

In the dual tube rotary percussion drilling method, the work object is installed safely and securely under protection of the borehole wall by the outer rods, then it can save the time and effort of washing and/or re-drilling.

The percussion function, furthermore, leads high drilling performance even in the strongly collapsible strata and the hard rock or boulders zone, and then the construction time shall be reduced.

According to HP of the Ministry of Land, Infrastructure, Transport and Tourism, however, there are approximately 1.1 million spots in danger of landslide outbreak, in which the ratio of countermeasures taken is only 23 %, therefore it is required to take prompt countermeasures.

Originally, the single tube rotary drilling method is applied for a borehole drilling, so that the collapse of the borehole wall used to occur depending on the geological character resulting that the drilling to the predetermined depth or the installation of the work object into the drilled borehole has difficulty

In the dual tube rotary percussion drilling method, the work object is installed safely and securely under protection of the borehole wall by the outer rods, then it can save the time and effort of washing and/or re-drilling.

The percussion function, furthermore, leads high drilling performance even in the strongly collapsible strata and the hard rock or boulders zone, and then the construction time shall be reduced.

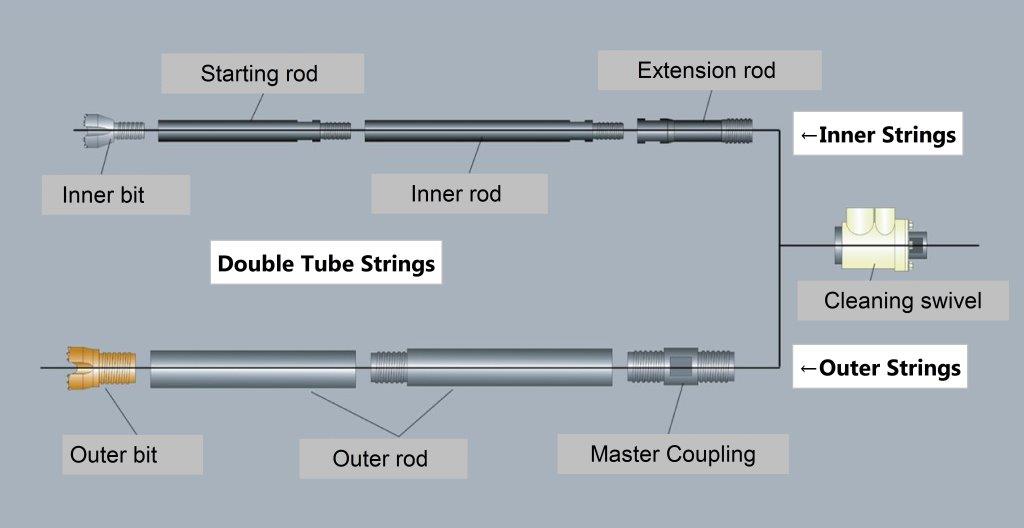

Exposition of the Solution

The dedicated drilling tools are basically composed of the inner and outer strings, and drilling is done in the state of the dual tube strings.

From the inlet port of the cleaning swivel, the drilling water is sent into the inner rod.

With the drilling water, cuttings (slime) crushed by the inner and outer bits are removed from the borehole bottom and discharged from the cleaning swivel outlet port through the gap of the inner and outer rods.

When the drilling is completed to a predetermined depth, the inner rods are fully retracted and the work object is inserted to the borehole bottom through the outer rods.

Because the outer rods protect the borehole wall, the work object can be inserted smoothly without any trouble such as borehole wall collapse.

Achievements of Examples

In 2012, at Tegucigalpa, the capital of Honduras Republic, “the Project for Landslide Prevention in Tegucigalpa metropolitan area” founded by the Japanese Grant Aid program has been executed.

In this project, the method to install a plurality of "water collection well" with "fan-shapely arranged water drainage holes" was adopted for the first time in the Central American region, thus the Allow Drill (Rotary Percussion Drill) has been utilized successfully and effectively.

In this project, the method to install a plurality of "water collection well" with "fan-shapely arranged water drainage holes" was adopted for the first time in the Central American region, thus the Allow Drill (Rotary Percussion Drill) has been utilized successfully and effectively.

Corporate Profile

Koken Boring Machine Co., Ltd.

1F Mejiro Nakano Bldg, 2-17-22 Takada, Toshima-ku, Tokyo 171-8572, JAPAN

Tel. : +81-3-6907-7515

E-mail : abekoken-boring.co.jp

Website : http://www.koken-boring.co.jp/e/index.htm