Bosai Solution ID : JBP00123

Implant™ Waterproof Wall

Protecting important facilities from inundation caused by a flood and a storm surge

Hazard

Solution Purpose

Solution Theme

Technology Subject

Advantages

Recently torrential rainfall has occurred more frequently in various countries in the world, causing severe floods and sediment-related disasters. The overflow of rivers has caused flooding damage in public facilities, factories, and residences. In addition, not only humans and the economy are damaged but disruptions such as power outages and water shortages have also significantly impacted critical lifelines.

Business continuity is a social responsibility for companies that support socio-economic development. Additionally, companies are required to ensure preparedness against disasters through BCP (Business Continuity Plan) to fulfill their duty.

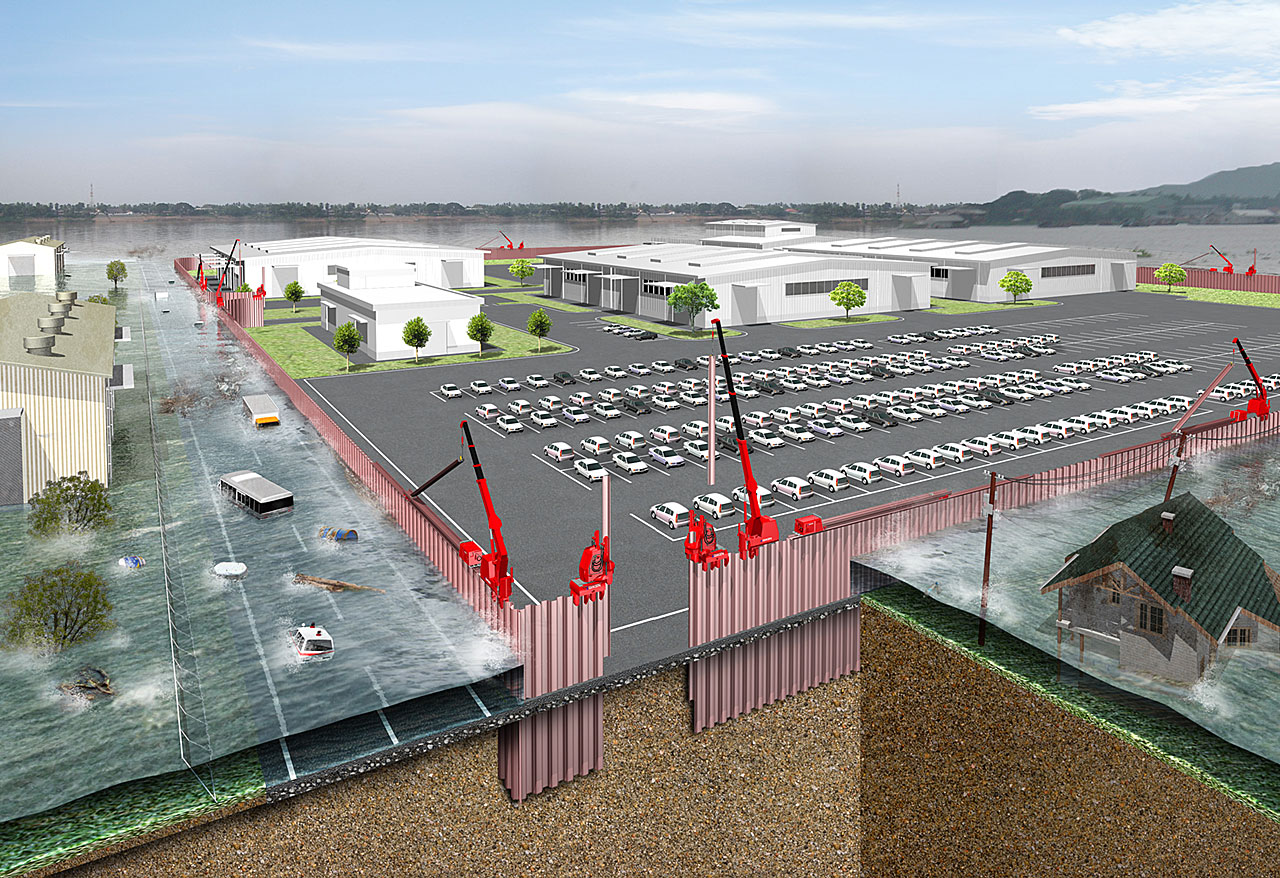

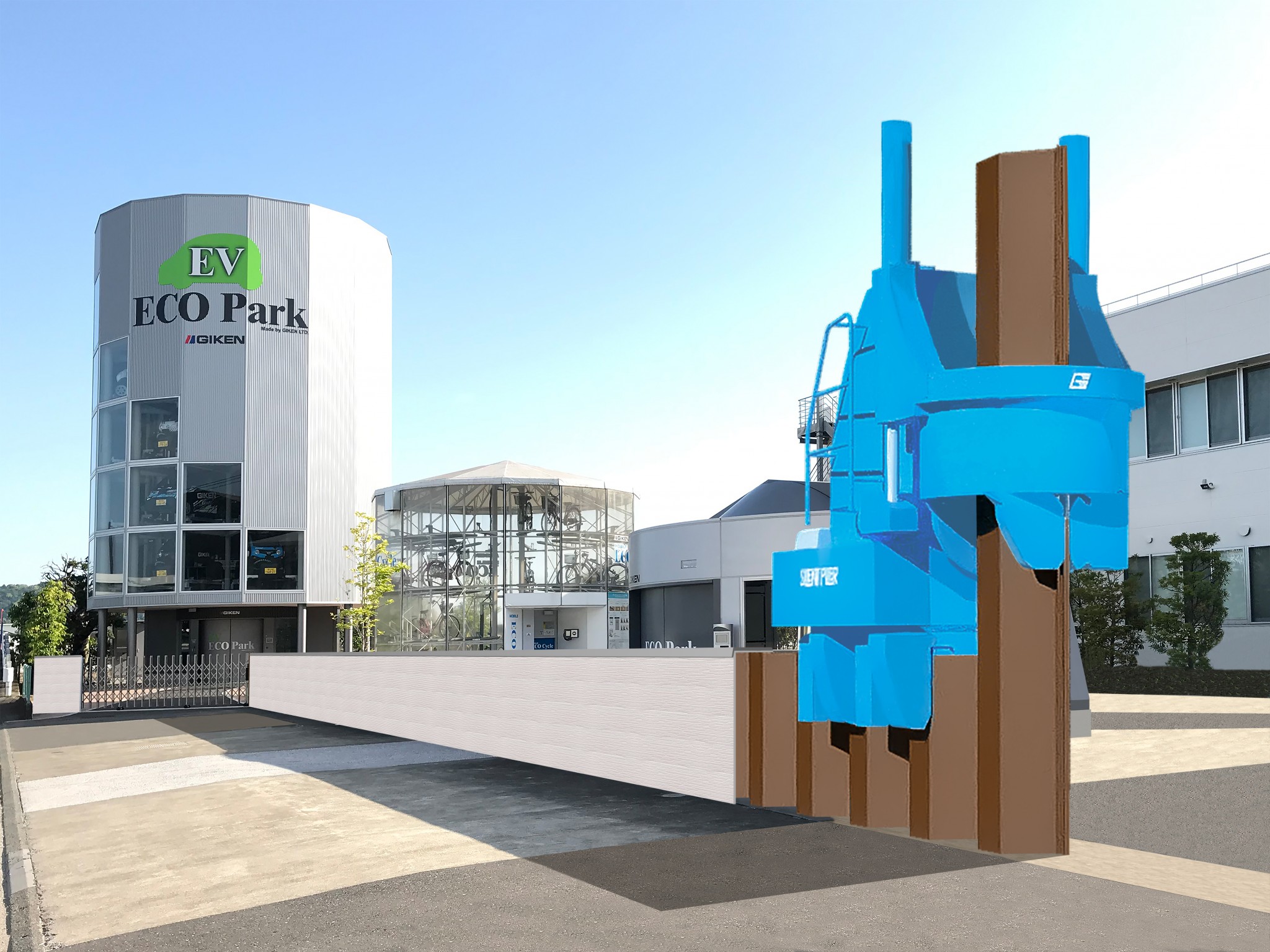

Implant™ Waterproof Wall serves as a defense measure against water disasters. It can be rapidly constructed by installing structural members (such as steel sheet piles) into the ground, effectively preventing facilities from being submerged in water.

Business continuity is a social responsibility for companies that support socio-economic development. Additionally, companies are required to ensure preparedness against disasters through BCP (Business Continuity Plan) to fulfill their duty.

Implant™ Waterproof Wall serves as a defense measure against water disasters. It can be rapidly constructed by installing structural members (such as steel sheet piles) into the ground, effectively preventing facilities from being submerged in water.

Solution Illustrated

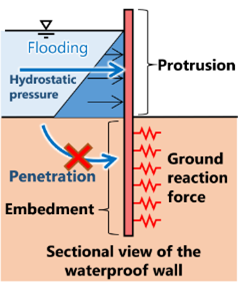

The Implant Waterproof Wall is a self-supporting structure that embeds steel sheet piles into the ground. These steel sheet piles, which have also been employed as retaining walls for roads and river revetments, boast a successful track record in sealing levees to prevent water leakage. Moreover, the wall’s protruding section prevents overtopping during floods, while the embedded portion safeguards against underground infiltration, mitigating the occurrence of boiling and piping phenomena.

Background

Flooding situation at Rojana Industrial Park in Thailand

Sourse:”Ministry of Land, Infrastructure, Transport and Tourism (MLIT) website”https://www.mlit.go.jp/river/bousai/main/saigai/kisotishiki/index3.html

In response to severe flood damage caused by torrential rains that have been increasing in recent years, the demand for flood prevention measures is increasing nationwide at the urging of the government. Under such circumstances, the actual results of Implant Waterproof Walls using steel sheet piles as one of the impervious walls are increasing.

Exposition of the Solution

[press-in method]

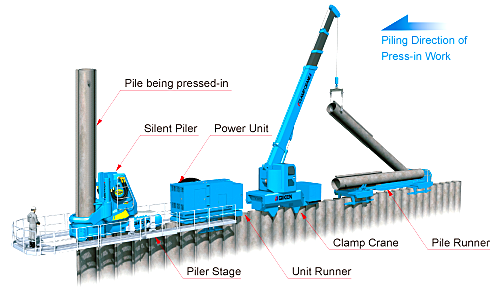

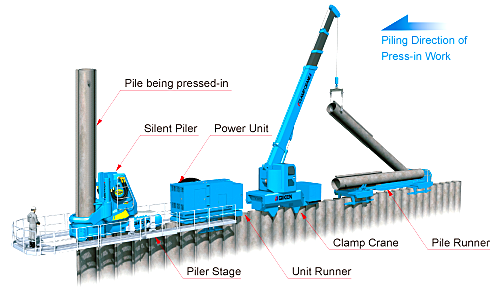

The press-in method is one of the methods for installing prefabricated piles into the ground to a predetermined depth. In the press-in method, the next pile presses into the ground by the hydraulic static load by grabbing installed piles using the extraction resistance force of reaction piles as a reaction force.

Compared to other installation methods, the press-in method has the advantage of generating less vibration and noise in the surrounding environment, not disturbing the ground, and not generating sludge.

Furthermore, since the reaction force is obtained from the completed pile, the weight of the press-in machine itself is not required, and the construction machine can be made lightweight and compact. Therefore, it can be applied to various conditions of job sites such as narrow spaces.

[GRB System™]

GRB System™ is an innovative installation of the press-in principle, which obtains reaction force from completed piles. Operating all machinery and equipment on completed piles eliminates the need for any temporary work and allows all processes of press-in construction, such as pile transportation, installation, and pressing in to be completed only on the piles.

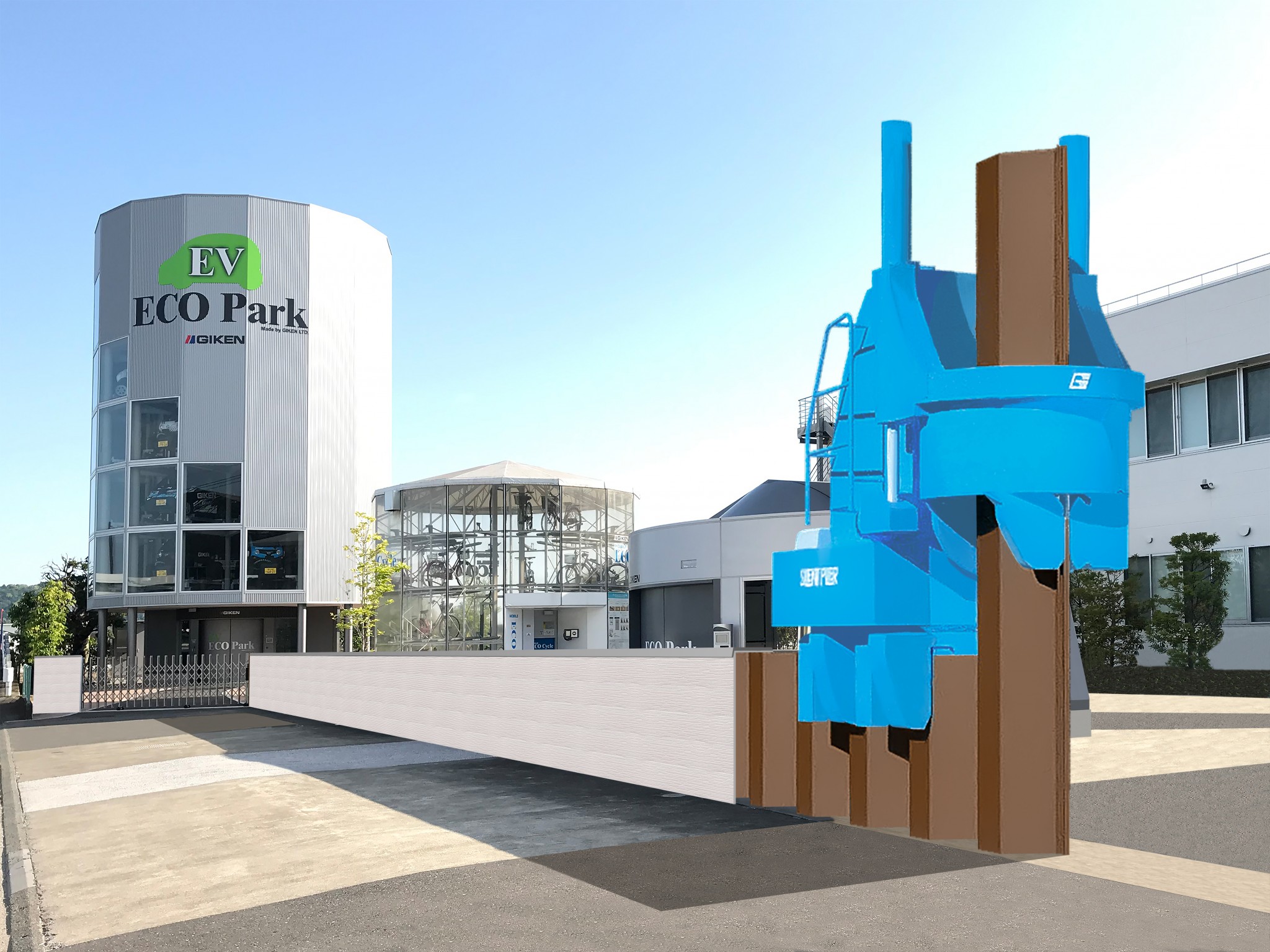

[Surfacing Material] ※Concrete products, siding walls, etc.

GRB System enables rapid systematization to install surfacing material from the driven sheet pile wall. Even in narrow areas around factories or in conditions close to existing structures, it has become possible to supply materials and loading and unloading operations on the pile.

The press-in method is one of the methods for installing prefabricated piles into the ground to a predetermined depth. In the press-in method, the next pile presses into the ground by the hydraulic static load by grabbing installed piles using the extraction resistance force of reaction piles as a reaction force.

Compared to other installation methods, the press-in method has the advantage of generating less vibration and noise in the surrounding environment, not disturbing the ground, and not generating sludge.

Furthermore, since the reaction force is obtained from the completed pile, the weight of the press-in machine itself is not required, and the construction machine can be made lightweight and compact. Therefore, it can be applied to various conditions of job sites such as narrow spaces.

[GRB System™]

GRB System™ is an innovative installation of the press-in principle, which obtains reaction force from completed piles. Operating all machinery and equipment on completed piles eliminates the need for any temporary work and allows all processes of press-in construction, such as pile transportation, installation, and pressing in to be completed only on the piles.

[Surfacing Material] ※Concrete products, siding walls, etc.

GRB System enables rapid systematization to install surfacing material from the driven sheet pile wall. Even in narrow areas around factories or in conditions close to existing structures, it has become possible to supply materials and loading and unloading operations on the pile.

Achievements of Examples

Kochi 3rd Factory and RED HILL 1967 (Akaoka Town, Kanan City)

Assuming the seismic intensity and tsunami flooding of the Nankai Trough Earthquake

・Maximum seismic intensity: 6 to 7

・Max. inundation depth: 3.0~5.0m

・Time to reach 30cm depth: 40-60 minutes

We are preparing for the early resumption of operations by building an Implant Waterproof Wall in response to anticipated damage (as described above).

Corporate Profile

GIKEN SEKO CO., LTD.

75-1 Minato Urayasu-shi Chiba 279-0024 Japan

Tel. : +81-47-318-9111

E-mail : consulgiken.com

Website : https://www.gikenseko.co.jp/for-english/